Indonesia is one of the large emitters of greenhouse gases in the world, mainly due to its reliance on coal for power generation such as PLTU Paiton with 4600 MW total production capacity. However, the government has recently announced a new target for decarbonization: to achieve net-zero emissions by 2060. This is a significant improvement from the previous goal of reducing emissions by 29% by 2030. Carbon capture and storage (CCS) is a technology that can reduce greenhouse gas emissions by capturing carbon dioxide (CO2) from large point sources, such as power plants, and storing it underground in geological formations (eg. Depleted Arun field). However, CCS projects face many technical, economic, and regulatory challenges, especially in terms of ensuring the long-term integrity and safety of CO2 storage. This is where MRV (measurement, reporting, and verification) comes in. MRV is a set of processes and procedures that aim to monitor the performance and environmental impacts of CCS projects, as well as to report and verify the amount and permanence of CO2 stored. MRV is essential for building trust and confidence among stakeholders, such as regulators, investors, and the public, as well as for supporting the development of carbon markets and policies. In this article, we will describe the main steps of MRV for CCS projects, which can be broadly divided into three phases: pre-injection, injection, and post-injection. Each phase has different objectives, methods, and requirements for MRV, depending on the characteristics of the project and the storage site.

One of the key steps in ensuring the safety and effectiveness of carbon capture and storage (CCS) is the pre-injection phase, where the site characteristics and potential risks are assessed. The pre-injection phase of MRV involves collecting baseline data on the geological, hydrogeological, geochemical, and geomechanical properties of the storage site and its surroundings. This data is used to create a geological model of the site, which describes the main features and processes that affect the behaviour of CO2 in the subsurface. The geological model is then used to develop a dynamic model, which simulates the injection and migration of CO2 under different scenarios and conditions. The dynamic model is a key tool for predicting the long-term fate and impact of CO2 in the storage site, as well as for designing the injection strategy and the monitoring plan.

The injection phase of MRV covers the period from when CO2 is injected into the storage site until the site is closed and transferred to a long-term steward. During this phase, MRV activities include:

- Monitoring the injection rate, pressure, temperature, and composition of the CO2 stream

- Tracking the CO2 plume migration and distribution within the storage formation

- Detecting any potential leakage of CO2 from the storage site to the surface or other formations

- Measuring the changes in pressure, temperature, and geochemical properties of the storage formation and surrounding rocks

- Reporting the amount and location of injected CO2 to relevant authorities and stakeholders

- Verifying the accuracy and reliability of the monitoring and reporting data

The injection phase of MRV requires a combination of different methods and technologies, such as:

- Well logging and testing

- Geophysical surveys (e.g., seismic, gravity, electromagnetic)

- Geochemical sampling and analysis (e.g., soil gas, groundwater, surface water)

- Surface flux measurements (e.g., eddy covariance, chamber methods)

- Remote sensing (e.g., satellite, aerial, drone)

The injection phase of MRV is a dynamic and adaptive process that depends on the characteristics of each CCS project. The design and implementation of MRV plans should consider the site-specific conditions, objectives, risks, uncertainties, costs, and benefits of CCS.

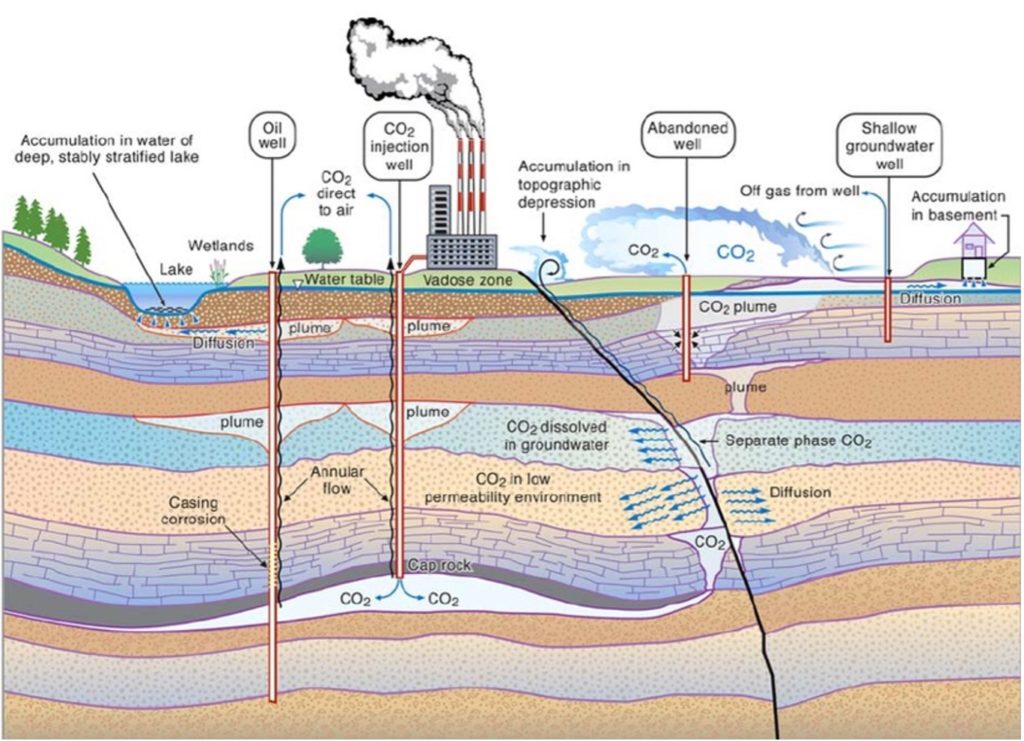

The post-injection phase involves monitoring the behaviour and fate of the injected CO2 in the subsurface, assessing the environmental impacts and risks, and ensuring the long-term integrity and safety of the storage site. One of the key challenges for post-injection MRV is how to detect CO2 leakage from the storage site. CO2 leakage can occur through natural or artificial pathways, such as faults, fractures, wells, or pipelines. CO2 leakage can have negative consequences for the environment, human health, and the effectiveness of CCS. Therefore, it is important to have reliable and accurate methods to monitor and measure CO2 leakage. Some of the common methods to detect CO2 leakage include surface and subsurface measurements of CO2 concentration, pressure, temperature, seismic activity, soil gas flux, groundwater quality, and vegetation health. During this phase, the CO2 plume is expected to stabilize and migrate slowly within the storage formation, while undergoing various trapping mechanisms that enhance its security. The main objectives of verifying CO2 storage permanence during the post-injection phase are:

- To confirm that the CO2 plume behaves as predicted by the dynamic models and does not pose any risk of leakage or adverse impacts on the environment or human health.

- To demonstrate compliance with the regulatory requirements and the contractual obligations of the storage operators and owners.

- To provide feedback and learning for future CCS projects and improve the public confidence and acceptance of CCS as a climate mitigation option.

To achieve these objectives, a comprehensive MRV plan should be developed and implemented for each CCS project, covering all stages of the project lifecycle, including the post-injection phase. The MRV plan should specify the monitoring techniques, methods, frequency, duration, and reporting procedures that will be used to verify CO2 storage permanence during the post-injection phase. The MRV plan should also define the performance criteria and thresholds that will trigger corrective actions or contingency plans in case of any anomalies or deviations from the expected behaviour of the CO2 plume. In general, monitoring during the post-injection phase should be more frequent and intensive in the early years after injection cessation, when the CO2 plume is still relatively dynamic and prone to pressure changes. As time passes and the CO2 plume stabilizes and becomes more securely trapped within the storage formation, monitoring can be reduced or discontinued. However, some level of monitoring may be required for a long period (e.g., decades or centuries) to ensure that no leakage or adverse impacts occur in the long term. Verifying CO2 storage permanence during the post-injection phase is a crucial component of MRV activities for CCS purpose. It provides evidence that CCS is a safe and effective climate mitigation option that can contribute to achieve net-zero emissions by 2060. It also supports the development and improvement of CCS technologies and best practices for future projects.